DATAMATH CALCULATOR MUSEUM

|

DATAMATH CALCULATOR MUSEUM |

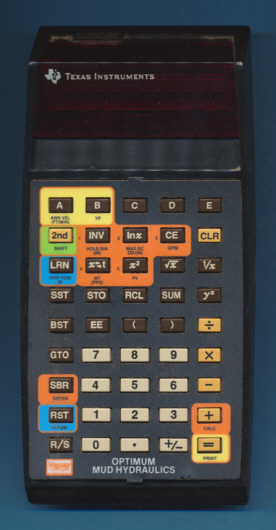

Texas Instruments TI-59 Optimum Mud Hydraulics

| Date of introduction: | 1980 | Display technology: | LED-stick |

| New price: | Display size: | 10 (8 + 2) | |

| Size: | 6.4" x 3.2" x

1.5" 162 x 81 x 37 mm3 |

||

| Weight: | 8.5 ounces, 240 grams | Serial No: | 9141376 |

| Batteries: | BP1A | Date of manufacture: | wk 21 year 1980 |

| AC-Adapter: | AC9131 | Origin of manufacture: | USA (ATA) |

| Precision: | 13 | Integrated circuits: | TMC0501E,

TMC0582, TMC0583,

TMC0571, TMC0594,

4*TMC0598 TMC0540 (tbd) |

| Logic: | AOS - 8 Pending Operations, 9 () | ||

| Memories: | 0-100 | ||

| Program steps: | 960-160 | Courtesy of: | Joerg Woerner |

![]()

The

innovative TI-59 was the perfect base for a lot of

customized calculators. The idea behind these products

was the novelty of the

Solid State Software Modules™ with up to 5000 program steps.

The

innovative TI-59 was the perfect base for a lot of

customized calculators. The idea behind these products

was the novelty of the

Solid State Software Modules™ with up to 5000 program steps.

The Optimum Mud Hydraulics application was developed in 1979 by

Magnet

Cove Barium Corporation,

later called Magcobar and programmed by Texas

Instruments into a Solid State Software Module. Read more about Oil

Muds.

Don't miss the IMCO DrilMod, the first

"library-on-a-chip" calculator module containing drilling application

programs developed for the TI-58 and TI-59.

We know five different approaches of the module expansion:

|

• Standard modules like the Master Library use only the small sticker above the A,B,C,D, and E keys. • Other modules like the Pool Water Analysis developed by Olin Corporation make use of a colorful keyboard mask. • Customized calculators like the USMC AV-8C calculator or insurance calculators sold by Allianz and others use special keyboard arrangements. • The CAL-Q-TAX calculator uses an extender instead the usual drop-in modules. • The Kodak Q-700 Program Adapter makes use of a snap-on cover with an individualized printing. |

Dismantling

the Optimum Mud Hydraulics calculator reveals a standard TI-59

calculator manufactured in Summer 1980.

Dismantling

the Optimum Mud Hydraulics calculator reveals a standard TI-59

calculator manufactured in Summer 1980.

Williard M. Johnson (1906-2000) founded Magnet Cove Barium

Corporation, later called Magco-bar or Magcobar, in 1940.

M-I Drilling Fluids, the world’s leading drilling and completion fluid

company, was formed when those operations were merged in 1986 with IMCO Services

(a subsidiary of the Halliburton Company). In 1987 M-I Drilling Fluids included

Swaco in its fold and majority ownership of the company changed from Dresser

Industries to Smith International, who bought 64% of the shares. M-I then

acquired several companies, Anchor Drilling Fluids (1996) Summit Drilling Fluids

(1997) and many others that continued to make them stronger in the market. In

1998 Smith International bought the remaining 36% of M-I from Halliburton.

Today, M-I SWACO employs approximately 13,000 persons in over 400 service

locations around the world.

© 2005 RAW Power Writing™

Commercial oil muds became available in 1942, when George L. Miller formed the Oil Base Drilling Fluids Company, Los Angeles, California. This company (now Oil Base, Inc.) supplied blown asphalt in the form of Black Magic®, a powder which was blended with a suitable oil at the well site. Properties of the blown asphalt and of the preferred diesel oil were specified. Naphthenic acid and calcium oxide were other components of the oil mud. Ready-mixed oil muds were supplied. and used muds were reconditioned.

Halliburton Oil Well Cementing Company, licensed under Shell's patents, in 1943 marketed an oil mud concentrate which contained blown asphalt, and tall oil soap formed in the oil phase by the reaction of tall oil with sodium hydroxide and sodium silicate. Salt (sodium chloride) could be added to counteract the effect of fresh water on water-soluble compounds of calcium and magnesium. The oil mud concentrate, when added to a water mud, formed an emulsion of oil in water. After Magnet Cove Barium Corporation took over the sale of Jeloil® in 1948, Jeloil E® was widely used in the preparation of water-in-oil emulsions.

In September 1948, the Ken Corporation (now merged into Imco Services Division of Halliburton Co.) of Long Beach. California, was formed to supply the oil mud compositions that had been developed by P.W. Fischer of Union Oil Co. These products did not contain air-blown asphalt. Instead, suspending and sealing properties were supplied by mixed alkali and alkaline earth soaps of resin acids. Subsequently, modifications were made in the resin products and other water-emulsifying agents were included in the composition. The liquid oil-mud concentrate was either mixed at the well site with crude oil (10°-24° API gravity) or diesel oil, or supplied already mixed from central plants.

From:

Composition and Properties of Drilling and Completion

Fluids

Gulf Professional Publishing; 5 edition (March 22, 1988)

Chapter: OIL-BASE DRILLING FLUIDS TECHNOLOGY page

63ff

If you have additions to the above article please email: joerg@datamath.org.

© Joerg Woerner, October 21, 2008. No reprints without written permission.